The iconic leather jacket, a timeless symbol of rebellion and self-expression, boasts a rich history and intricate manufacturing process. From raw animal hides to the finished product gracing store shelves, the journey is one of skilled craftsmanship and meticulous attention to detail. This article delves into the leather jacket manufacturing overview, exploring the key stages, materials, and challenges involved in bringing these coveted outerwear pieces to life.

Leather Jacket Manufacturing Process Overview

Stage 1: Sourcing the Raw Materials

The foundation of any exceptional leather jacket lies in the quality of its raw materials. Tanners meticulously select animal hides, primarily from cows, goats, and sheep, based on factors like thickness, texture, and presence of blemishes. These hides then undergo a multi-step tanning process, transforming them from perishable skin into durable and supple leather. Different tanning methods – chrome, vegetable, or a combination – imbue the leather with unique characteristics, influencing its final look and feel.

Stage 2: Design and Pattern Making

With the leather prepared, designers translate their vision into detailed blueprints. Using specialized software or traditional hand-drawn methods, they create intricate patterns that optimize material usage and ensure a perfect fit. Experienced pattern makers meticulously refine these patterns, considering factors like seam allowances, ease of movement, and the desired silhouette.

Stage 3: Cutting and Preparation

Skilled leather cutters transform the patterns into reality. Utilizing sharp blades and specialized equipment, they carefully cut each piece of leather with precision, minimizing waste and ensuring all parts align seamlessly. Before moving to assembly, the leather may undergo additional processes like buffing, sanding, or embossing to achieve the desired texture and visual effect.

Stage 4: Sewing and Assembly

With the individual components prepared, expert technicians bring the jacket to life. Industrial sewing machines, often guided by skilled hands, stitch the pieces together with robust seams. This stage requires careful attention to detail, ensuring proper reinforcement at stress points like elbows and shoulders. Zippers, buttons, and other hardware are meticulously attached, completing the jacket’s functionality and aesthetic.

Stage 5: Quality Control and Finishing Touches

Each jacket undergoes rigorous quality checks to identify and rectify any imperfections. This may involve visual inspections, strength tests, and even dye consistency checks. Once deemed flawless, the jacket receives its finishing touches. Depending on the design, this might involve hand-painting, distressing, or the application of protective coatings for weather resistance.

Beyond the Basics: Exploring Specialization and Sustainability

While the core manufacturing process remains similar across various brands and styles, several factors contribute to the final quality and price point of a leather jacket. High-end manufacturers often utilize superior leather grades, employ artisanal techniques like hand-sewing, and prioritize ethical sourcing practices. Additionally, the rise of sustainable practices sees some manufacturers exploring the use of vegetable-tanned leathers and recycled materials, catering to eco-conscious consumers.

The Human Touch: Real People, Real Experiences

The magic of leather jacket manufacturing lies not just in the machinery and processes, but also in the skilled individuals behind them. From tanners who understand the nuances of hide selection to cutters who transform patterns into precise pieces, each step involves dedicated professionals. Speaking to a leather artisan reveals a deep-rooted passion for the craft, often passed down through generations. They describe the satisfaction of creating timeless pieces that become cherished companions for their wearers.

-

Product on sale

Men’s Real Leather Bomber Jacket BlackOriginal price was: $199.99.$159.99Current price is: $159.99.

Men’s Real Leather Bomber Jacket BlackOriginal price was: $199.99.$159.99Current price is: $159.99. -

Product on sale

Warriors Viper Pilot Battlestar Galactica Jacket Brown Real Suede Leather JacketOriginal price was: $169.99.$139.99Current price is: $139.99.

Warriors Viper Pilot Battlestar Galactica Jacket Brown Real Suede Leather JacketOriginal price was: $169.99.$139.99Current price is: $139.99. -

Product on sale

Mens Motorcycle Brown Leather Handmade JacketOriginal price was: $169.99.$129.99Current price is: $129.99.

Mens Motorcycle Brown Leather Handmade JacketOriginal price was: $169.99.$129.99Current price is: $129.99. -

Product on sale

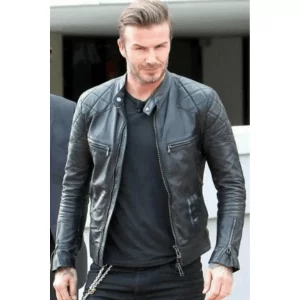

Mens David Beckham Black Real Leather Jacket.Original price was: $199.99.$149.99Current price is: $149.99.

Mens David Beckham Black Real Leather Jacket.Original price was: $199.99.$149.99Current price is: $149.99. -

Product on sale

Red Dead Redemption II – Arthur Morgan Tan Brown Real Leather Jacket – RDR2Original price was: $189.99.$139.99Current price is: $139.99.

Red Dead Redemption II – Arthur Morgan Tan Brown Real Leather Jacket – RDR2Original price was: $189.99.$139.99Current price is: $139.99. -

Product on sale

Men’s Slim Fit Bomber Hoodie Brown Biker Leather JacketOriginal price was: $179.99.$129.99Current price is: $129.99.

Men’s Slim Fit Bomber Hoodie Brown Biker Leather JacketOriginal price was: $179.99.$129.99Current price is: $129.99. -

Product on sale

Men’s New Motorcycle Black Biker Real Leather JacketOriginal price was: $179.99.$129.99Current price is: $129.99.

Men’s New Motorcycle Black Biker Real Leather JacketOriginal price was: $179.99.$129.99Current price is: $129.99. -

Product on sale

Men’s Cole Hauser TV Series Stylish Cowboy Black JacketOriginal price was: $189.99.$129.99Current price is: $129.99.

Men’s Cole Hauser TV Series Stylish Cowboy Black JacketOriginal price was: $189.99.$129.99Current price is: $129.99. -

Product on sale

Mass Effect 3 Mens N7 Cafe Racer Real Leather JacketOriginal price was: $169.99.$129.99Current price is: $129.99.

Mass Effect 3 Mens N7 Cafe Racer Real Leather JacketOriginal price was: $169.99.$129.99Current price is: $129.99.

Wrapping Up

The journey of a leather jacket, from raw hide to finished product, is a testament to human ingenuity and dedication. Understanding the intricate steps involved in leather jacket manufacturing fosters a deeper appreciation for the quality, craftsmanship, and often, the rich history embodied in each piece. So, the next time you slip on your favorite leather jacket, remember the skilled hands and passionate individuals who brought it to life, transforming humble hides into timeless treasures.